Water & BTU Thermal Energy Metering

Utility Water Meter Integration

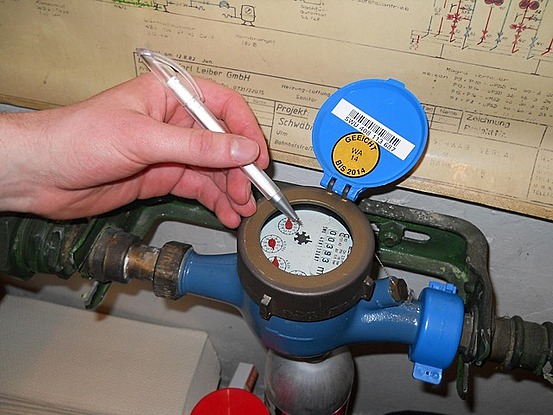

Integration of utility water meters are typically performed through pulse outputs installed by the utility company. Since the water meter is an asset for the utility company, we request that the end user makes this request for an output. Once this output is provided, Emergent will provide the necessary hardware to integrate the pulses and convert the pulses back to flow as cubic feet or gallons.

This integration method provides the most accurate measurement for the site's water consumption since the pulses are originating from the utility gas meter itself. The main utility water meter's output is being monitored, this does assume the utility water meter to be 100% accurate regardless of its age, make and model.

New Inline Volumetric Flow Water

Sub-meter

New inline water submeters are recommended for locations where power is limited and temperature range might be a concern for other types of meters. Installation of an inline water meter will require additional mechanical labor to thread or flange installation of the new meter.

Inline water meters are significantly more cost effective on smaller diameter pipes that are 2" diameter and less since they can be installed through pro-press. Once pipe size exceeds 2" the better option might be to use ultrasonic water meters. The added cost to use ultrasonic water metering will be offset by the savings from the simpler metering installation.

Ultrasonic Clamp-On Flow Water Meter

Ultrasonic water submeters are recommended for large pipe diameter pipe installations due to the increased cost and complexity of installation from inline meters. These non-invasive installations can happen at any time and provides great flexibility for rapid implementation.

Accuracy might be a concern for these meters during low flow conditions since ultrasonic meters measure velocity and applies a low flow condition parameter to eliminate noise. On large diameter pipes during low water velocity conditions, these meters might ignore small leaks in main headers and branch circuits.

BTU Meters and Ultrasonic Water Meters

Overview of Ultrasonic Flow Meters

Ultrasonic flow meters are advanced non-intrusive flow measurement devices used to track the flow of liquids, gases, and steam in a variety of industrial applications. These meters use high-frequency sound waves to determine flow velocity, making them a popular choice for water treatment plants, HVAC systems, oil and gas operations, and compressed air monitoring. With high accuracy, minimal pressure drop, and no moving parts, ultrasonic flow meters provide a reliable, cost-effective solution for optimizing industrial processes.

Ultrasonic flow meters are advanced non-intrusive flow measurement devices used to track the flow of liquids, gases, and steam in a variety of industrial applications. These meters use high-frequency sound waves to determine flow velocity, making them a popular choice for water treatment plants, HVAC systems, oil and gas operations, and compressed air monitoring. With high accuracy, minimal pressure drop, and no moving parts, ultrasonic flow meters provide a reliable, cost-effective solution for optimizing industrial processes.

How Ultrasonic Flow Meters Work

Ultrasonic flow meters operate using two primary principles:

Ultrasonic flow meters operate using two primary principles:

1. Transit-Time Ultrasonic Flow Meters

- Best for clean fluids such as water, natural gas, and steam.

- Utilize two transducers placed upstream and downstream of a pipe.

- Measure the time it takes for an ultrasonic signal to travel with and against the flow.

- The time difference is used to calculate flow velocity and total volumetric flow.

- High precision and commonly used in municipal water supply, energy management, and industrial automation.

- Best for clean fluids such as water, natural gas, and steam.

- Utilize two transducers placed upstream and downstream of a pipe.

- Measure the time it takes for an ultrasonic signal to travel with and against the flow.

- The time difference is used to calculate flow velocity and total volumetric flow.

- High precision and commonly used in municipal water supply, energy management, and industrial automation.

2. Doppler Ultrasonic Flow Meters

- Ideal for slurries, wastewater, and contaminated fluids.

- Emit sound waves that bounce off particles and bubbles within the fluid.

- Measure the frequency shift (Doppler effect) to determine the flow rate.

- Best for applications involving pulp and paper, food and beverage, and mining operations.

- Ideal for slurries, wastewater, and contaminated fluids.

- Emit sound waves that bounce off particles and bubbles within the fluid.

- Measure the frequency shift (Doppler effect) to determine the flow rate.

- Best for applications involving pulp and paper, food and beverage, and mining operations.

Types of Ultrasonic Flow Meters: Clamp-On vs. Inline

Clamp-On Ultrasonic Flow Meters

- Mounted externally on the pipe, requiring no modifications.

- Non-intrusive installation eliminates downtime and prevents contamination.

- Perfect for large pipelines and temporary flow monitoring applications.

- Mounted externally on the pipe, requiring no modifications.

- Non-intrusive installation eliminates downtime and prevents contamination.

- Perfect for large pipelines and temporary flow monitoring applications.

Inline Ultrasonic Flow Meters

- Installed directly within the pipeline for maximum accuracy and efficiency.

- Commonly used in high-precision industrial processes, compressed air systems, and high-pressure gas applications.

- Installed directly within the pipeline for maximum accuracy and efficiency.

- Commonly used in high-precision industrial processes, compressed air systems, and high-pressure gas applications.

Key Benefits of Ultrasonic Flow Meters

✅ High Accuracy & Repeatability – Especially in transit-time models for clean liquids and gases.

✅ Minimal Pressure Drop – Unlike orifice plate and turbine meters, ultrasonic flow meters do not obstruct the flow.

✅ Low Maintenance Costs – No moving parts reduce wear and tear, leading to long-term savings.

✅ Real-Time Data Monitoring – IoT-compatible for remote flow monitoring and system optimization.

✅ Versatile Applications – Suitable for oil & gas, HVAC, municipal water distribution, pharmaceutical manufacturing, and compressed air flow measurement.

Limitations of Ultrasonic Flow Meters

❌ Higher Initial Cost – More expensive than traditional flow meters, but offset by long-term savings.

❌ Requires Proper Installation & Calibration – Alignment and pipe condition affect accuracy.

❌ Sensitivity to Air Bubbles & Particles – Transit-time models may struggle in fluids with excessive turbulence or contamination.

❌ Higher Initial Cost – More expensive than traditional flow meters, but offset by long-term savings.

❌ Requires Proper Installation & Calibration – Alignment and pipe condition affect accuracy.

❌ Sensitivity to Air Bubbles & Particles – Transit-time models may struggle in fluids with excessive turbulence or contamination.

Conclusion

Ultrasonic flow meters provide an accurate, reliable, and cost-effective solution for measuring liquid, gas, and steam flow across a wide range of industries. Whether for municipal water systems, compressed air networks, or high-pressure gas applications, these meters help businesses improve efficiency, reduce energy consumption, and optimize performance. Choosing the right ultrasonic flow meter depends on fluid characteristics, pipe size, and system requirements to ensure optimal accuracy and reliability.

For businesses looking to enhance compressed air monitoring, HVAC efficiency, or industrial automation, ultrasonic flow meters are a smart investment in precision and sustainability.

Ultrasonic flow meters provide an accurate, reliable, and cost-effective solution for measuring liquid, gas, and steam flow across a wide range of industries. Whether for municipal water systems, compressed air networks, or high-pressure gas applications, these meters help businesses improve efficiency, reduce energy consumption, and optimize performance. Choosing the right ultrasonic flow meter depends on fluid characteristics, pipe size, and system requirements to ensure optimal accuracy and reliability.

For businesses looking to enhance compressed air monitoring, HVAC efficiency, or industrial automation, ultrasonic flow meters are a smart investment in precision and sustainability.

Ultrasonic Water Flow Meter

Ultrasonic transit time flow meter. For measurement of water flow in open and closed loop water delivery systems. Ideal for installation onto potable water supplies where flow is fairly consistent

Ultrasonic Flow w/ Thermal BTU Meter (Energy Meter)

Ultrasonic transit time flow meter w/ surface mounted temperature (thermal) sensor. Designed for central heating or chilled water loops.

Handheld Ultrasonic Flow Meter

Ultrasonic transit time flow meter for temporary installation. Battery or plug powered. Verification meter for a permanently installed meters.