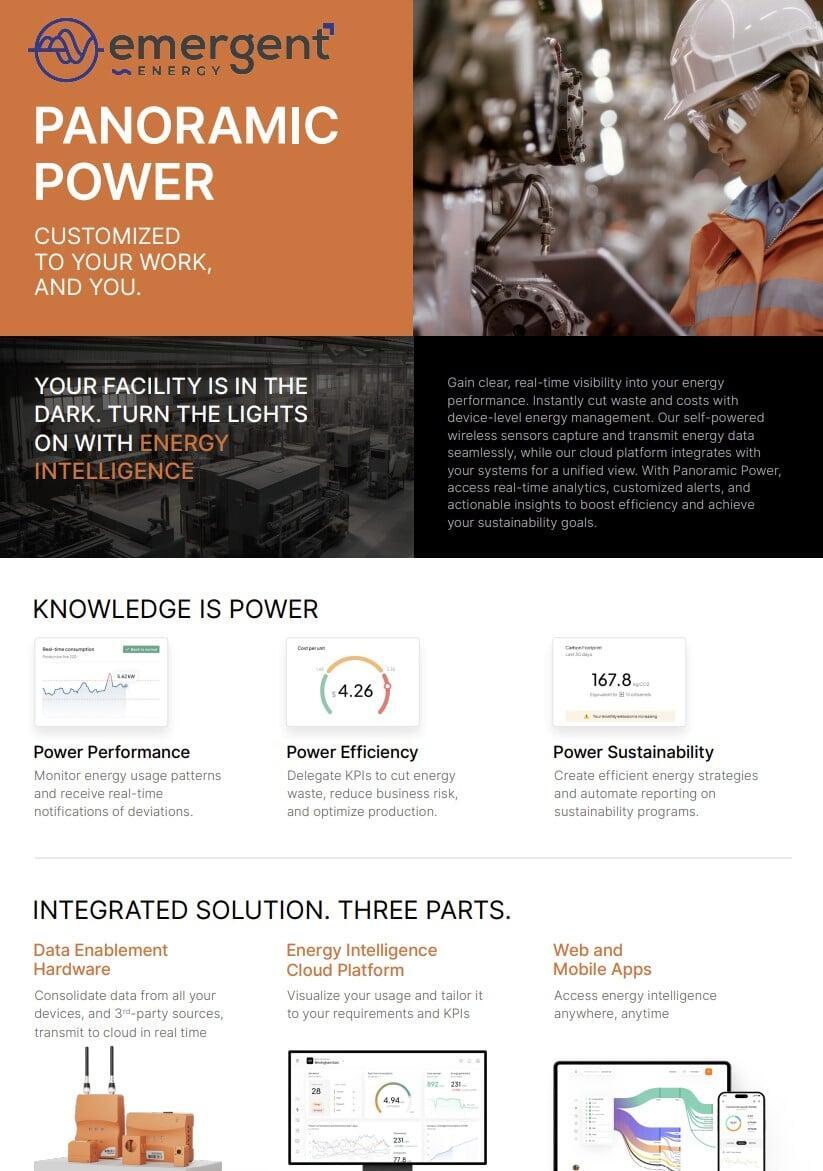

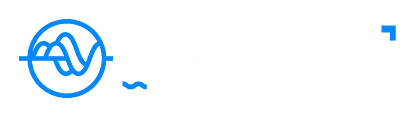

Comprehensive Energy Monitoring Platform For All Utilities

Delivering Operational and Energy Efficiency

Value for our customers

Value for our customers

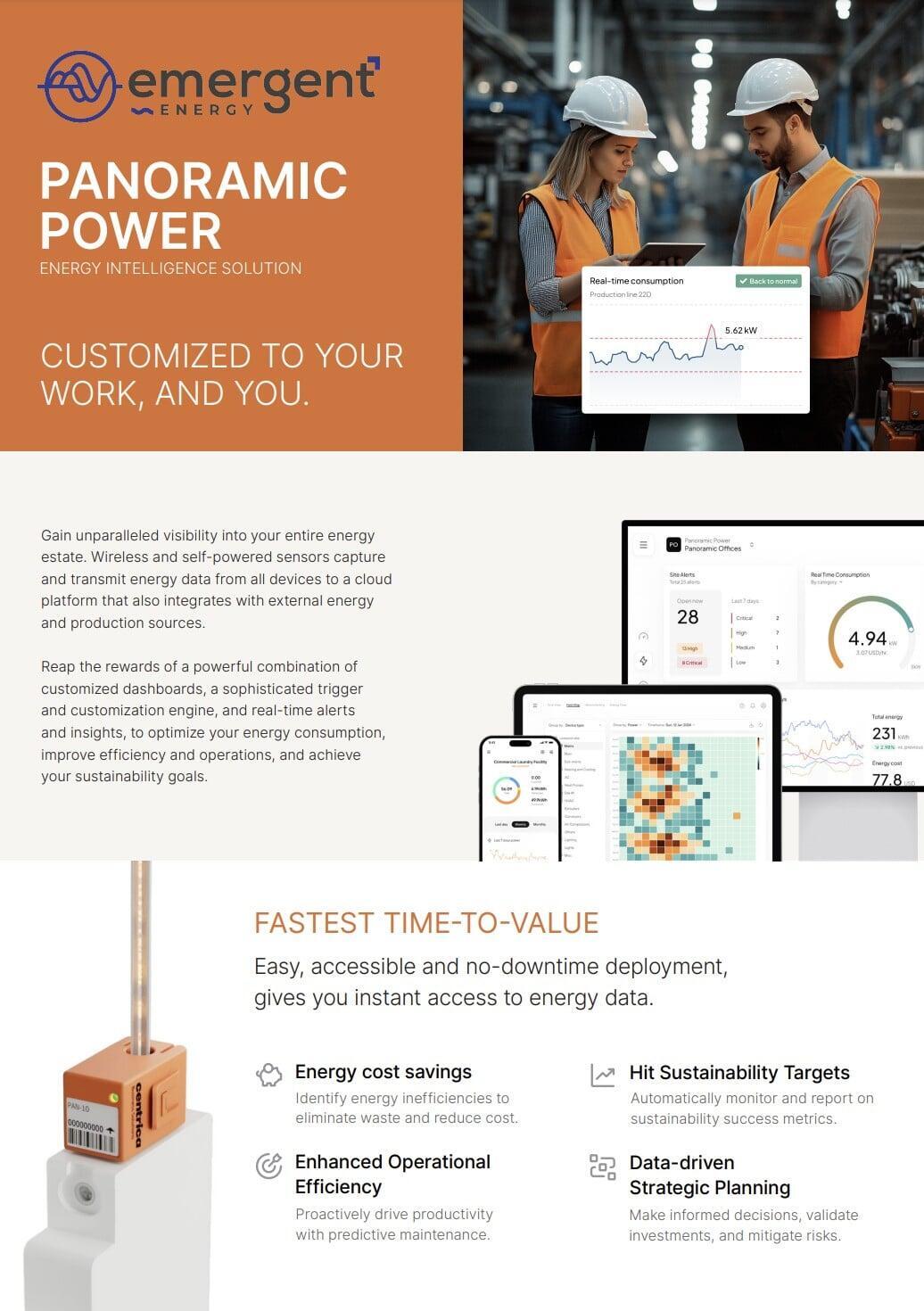

- Empower energy teams to own their process while creating a culture of process ownership

- Experience significant ROI and value - immediately following setup.

- Lower your electricity costs by proactively taking action when you identify inefficiencies and energy waste.

- Reduce the risk of equipment failure and costly downtime with predictive analytics and sophisticated alerts.

- Easily plan, monitor, and report on Net Zero and Decarbonization sustainability initiatives.

- Get an in-depth understanding of your energy estate with real-time, detailed analytics

- Monitor utility meters in real-time

- Submeter electric, natural gas, water, and other energy sources

- Monitoring space temperatures, system pressures and air quality

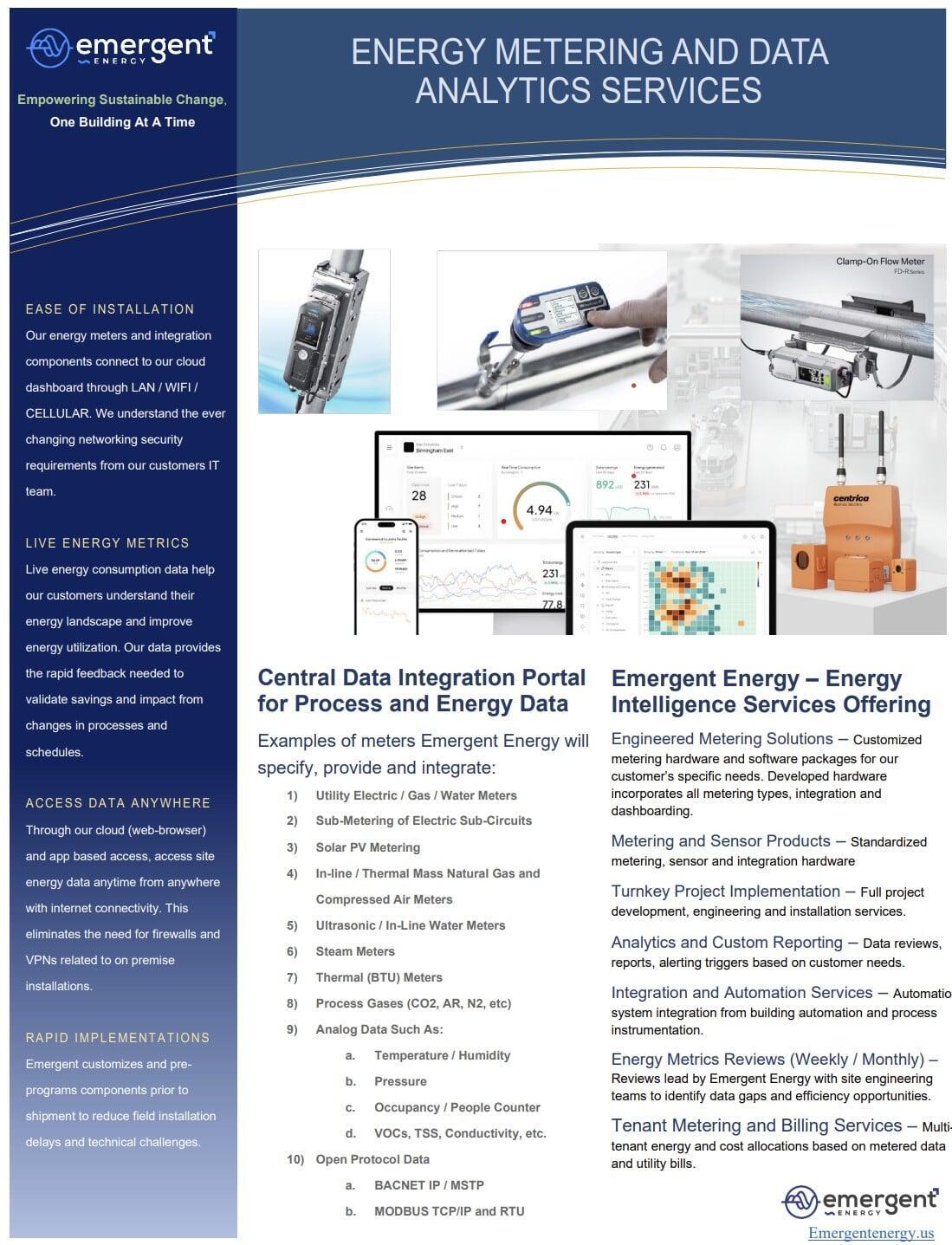

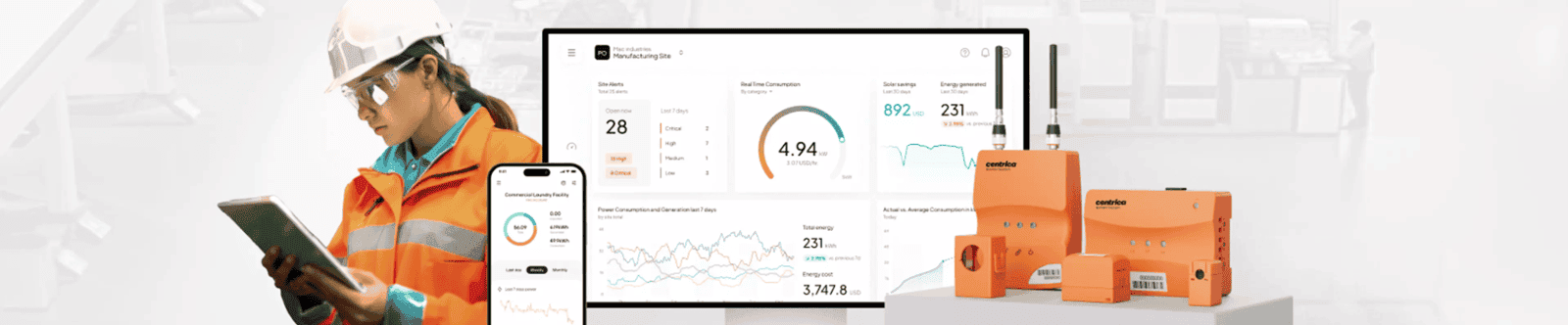

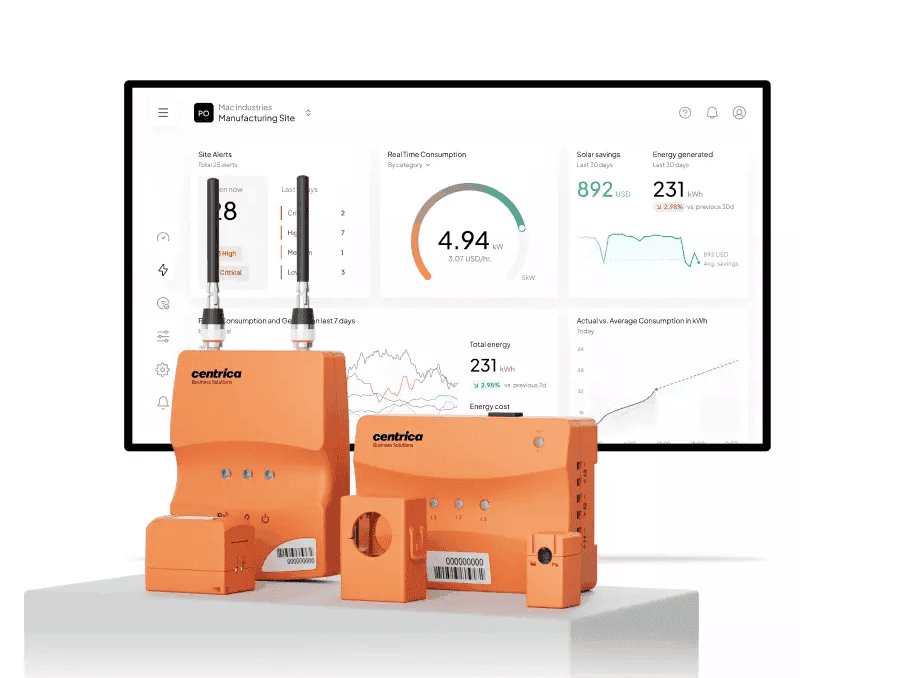

Electric Sensors & Cloud Integration

Electric Sensors & Cloud Integration

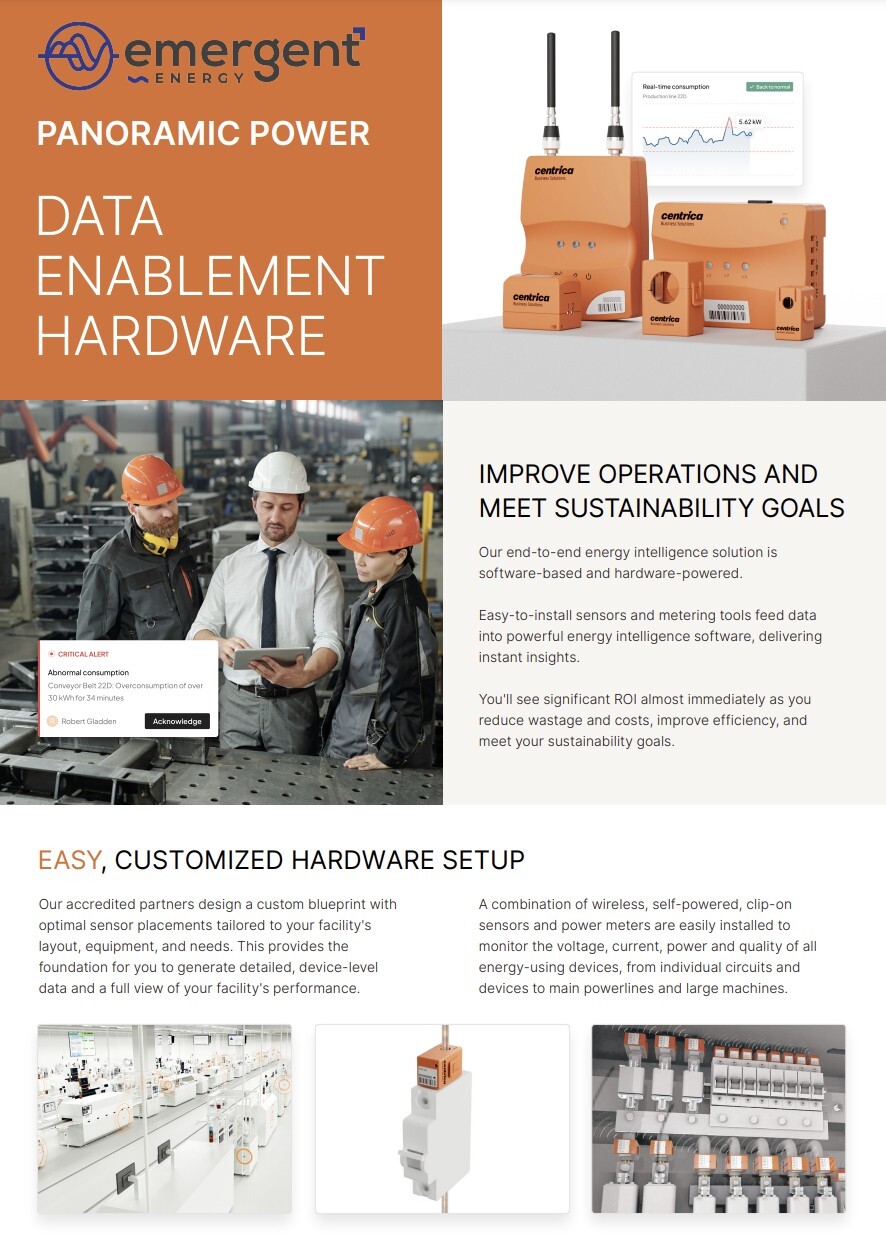

Collect real-time energy data at the device level, with wireless, maintenance-free sensors, that create a highly granular energy image.

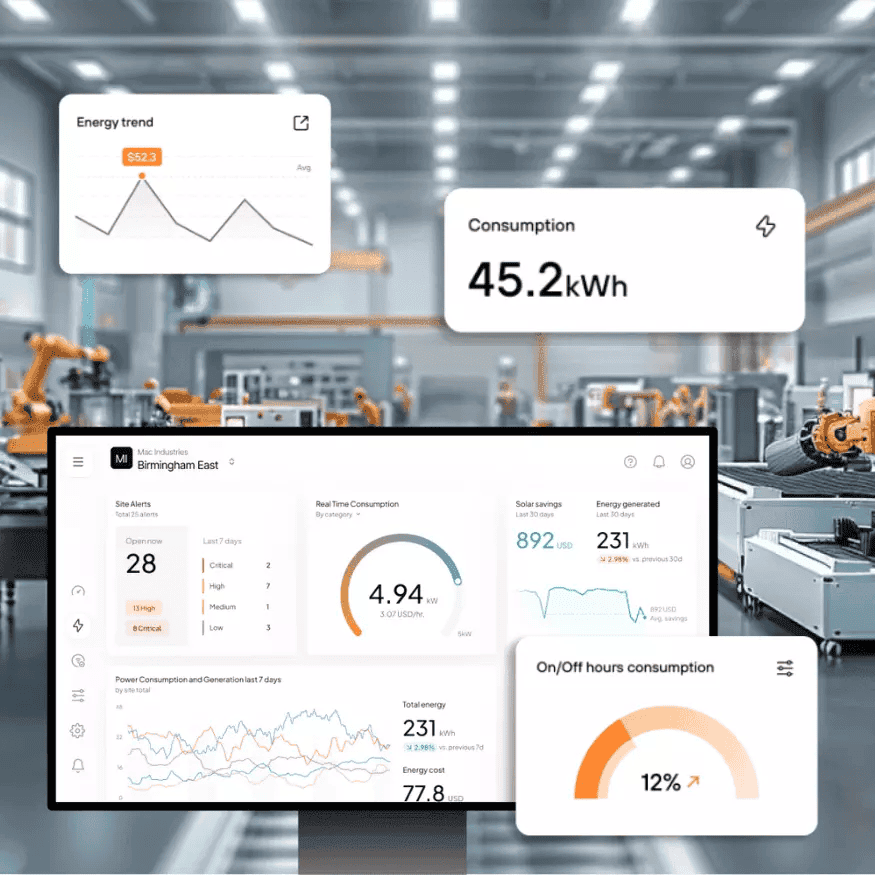

Web-Based Cloud AnalyticsDrive Operational Efficiency

Web-Based Cloud AnalyticsDrive Operational Efficiency

The sensors collect data and deliver it via the Panoramic Power® Gen 4+ bridge to the energy intelligence cloud platform for monitoring and analysis.

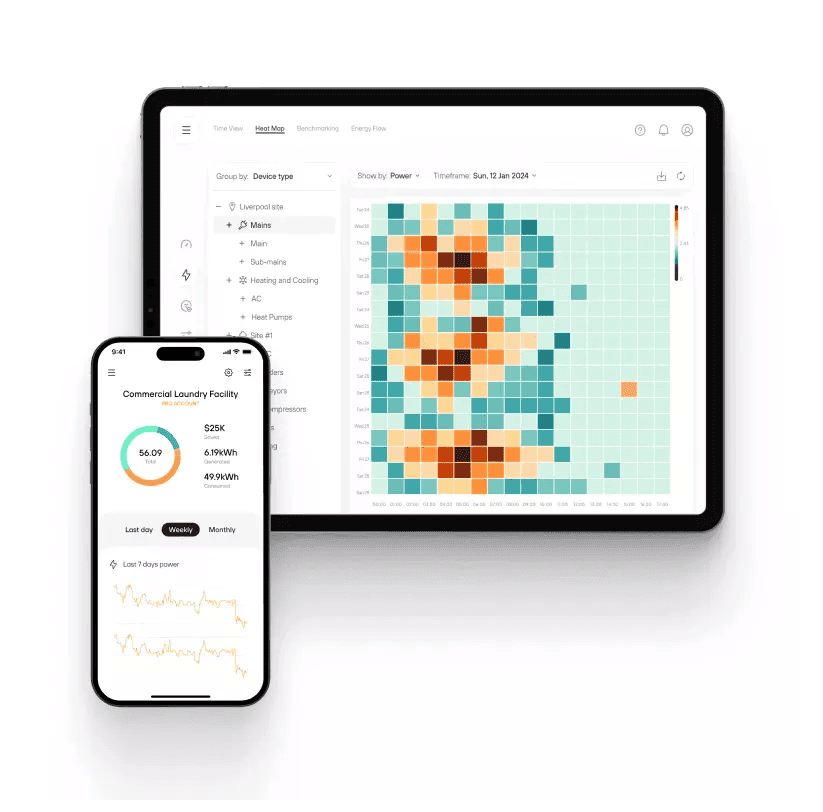

Web and Mobile App for Anytime, Anywhere Access

Web and Mobile App for Anytime, Anywhere Access

The cloud-based platform allows you to easily view and manage your energy from anywhere to make data-driven business and sustainability decisions.

Integration Platform for All Utilities

Natural Gas Utility Meters and Submeters

Natural gas utility meters and submeters provide accurate measurement and monitoring of gas consumption for commercial, industrial, and multi-tenant properties. Utility meters track total gas usage, while submeters allow for detailed monitoring at the equipment, tenant, or process level.

By implementing gas submetering, businesses can optimize energy efficiency, detect leaks, allocate costs fairly, and ensure compliance with energy regulations. Real-time data and analytics help reduce waste, improve system performance, and lower operating costs, making natural gas metering a crucial tool for effective energy management.

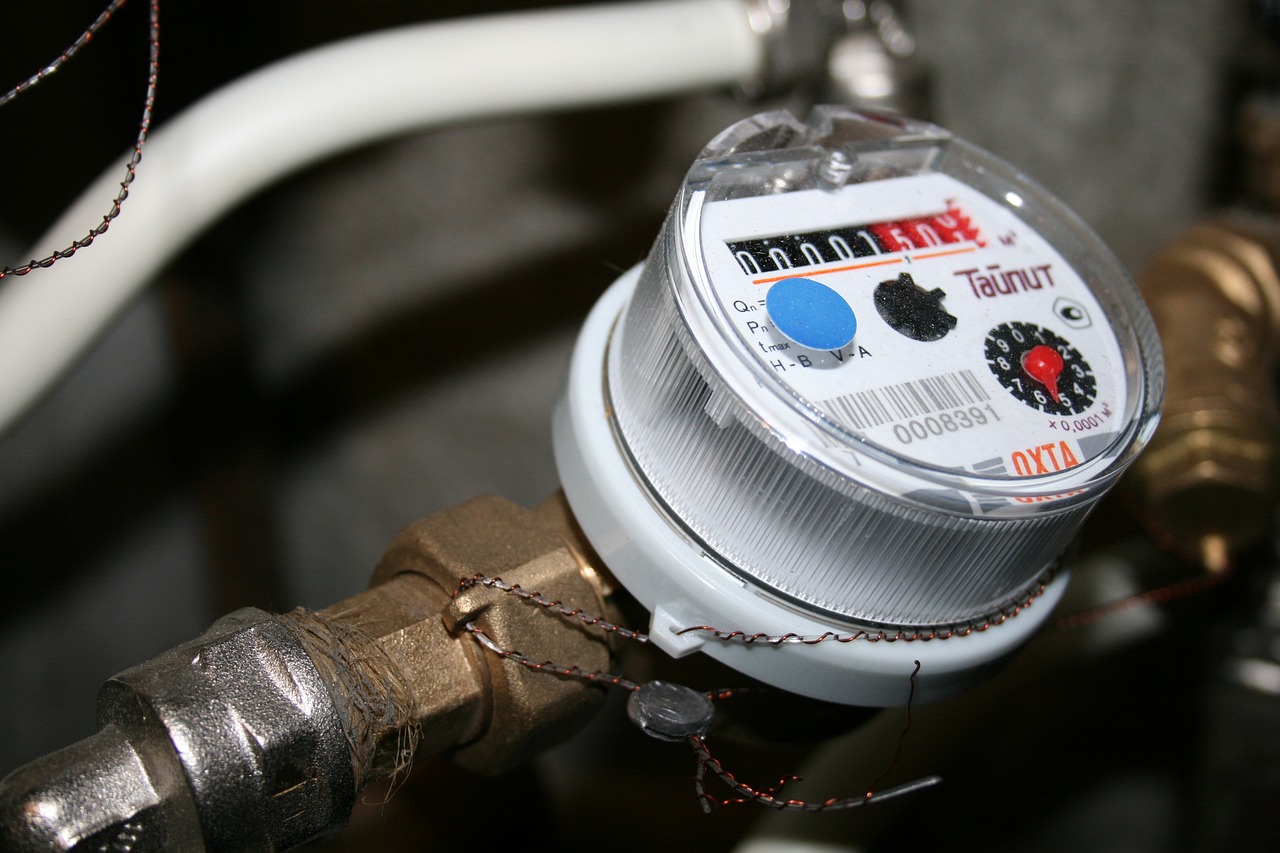

Water and BTU Submetering

Water and BTU Submetering

Utility water and thermal BTU submetering provide precise measurement of water consumption and thermal energy usage in commercial, industrial, and multi-tenant buildings. By tracking water flow and heat transfer in HVAC, district energy, and hydronic systems, submetering enables businesses to optimize efficiency, reduce waste, and allocate costs accurately.

With real-time monitoring and data analytics, organizations can identify inefficiencies, detect leaks, and ensure fair tenant billing. Implementing advanced submetering solutions supports sustainability goals, lowers operational expenses, and enhances overall system performance.

Electrical Main Service and Submetering (Electric Meters)

lectrical main service and submetering provide critical insights into energy consumption, enabling businesses to monitor, manage, and optimize their electricity usage. Main service meters track total facility energy use, while submeters break down consumption by department, tenant, or specific equipment.

By implementing electric submetering, organizations can identify inefficiencies, allocate costs accurately, and improve energy efficiency. Real-time monitoring and data analytics help reduce waste, lower operating expenses, and support sustainability initiatives. Whether for commercial buildings, industrial facilities, or multi-tenant properties, electric metering is a key tool for smarter energy management.

Steam Submetering - Central Header and Process Level Metering

Steam metering is essential for accurately measuring steam consumption, optimizing energy efficiency, and reducing operational costs in industrial and commercial facilities. By using advanced steam flow meters, businesses can monitor steam usage in real time, identify inefficiencies, and improve system performance. Proper steam metering enables precise billing, process control, and sustainability initiatives, ensuring that steam systems operate at peak efficiency while minimizing waste and emissions.

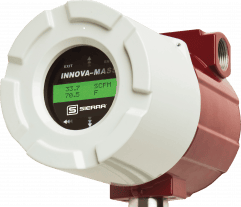

Compressed Air, Nitrogen (N2), CO2, Hydrogen (H2) Submetering

Compressed Air, Nitrogen (N2), CO2, Hydrogen (H2) Submetering

Submetering for compressed air, nitrogen (N₂), carbon dioxide (CO₂), and hydrogen (H₂) is essential for industries that rely on these gases for manufacturing, processing, and operational efficiency. By accurately measuring gas consumption at key points within a facility, businesses can detect leaks, optimize system performance, and reduce energy waste.

Advanced submetering solutions provide real-time data, enabling better cost allocation, predictive maintenance, and sustainability improvements. Whether for industrial production, food and beverage processing, or clean energy applications, precise gas monitoring helps drive efficiency, lower costs, and enhance operational reliability.

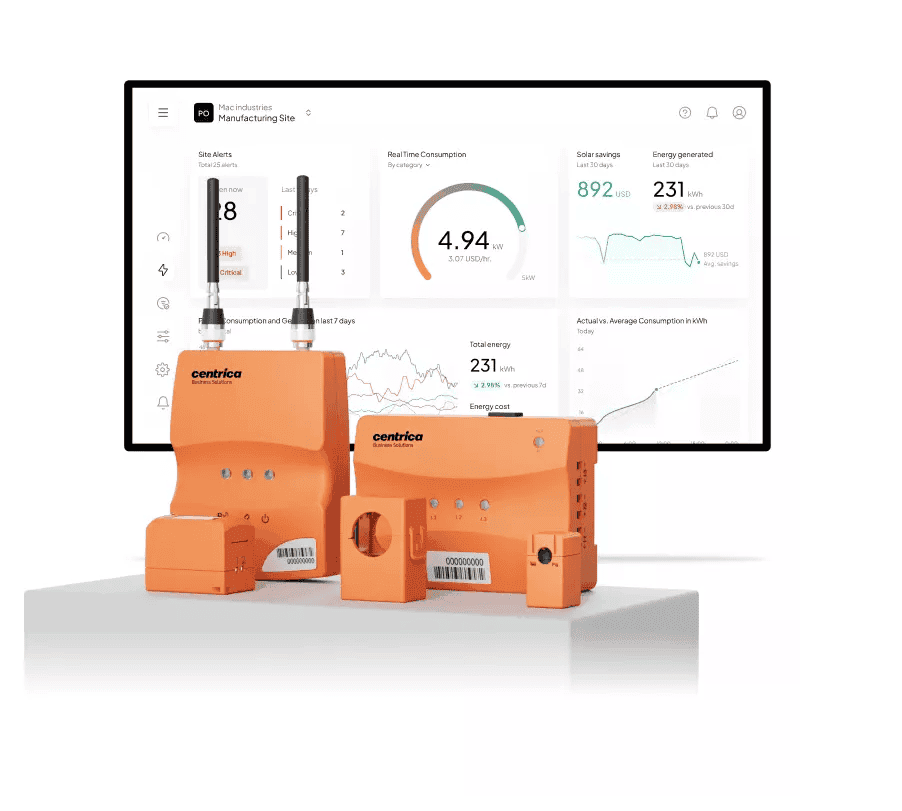

Energy Analytics, Reporting and Tenant Billing

Effective energy management begins with accurate data. Energy analytics and reporting provide real-time insights into energy consumption, helping businesses identify inefficiencies, reduce costs, and improve sustainability. By leveraging advanced monitoring systems, organizations can track energy usage across multiple sites, set performance benchmarks, and make data-driven decisions.

For multi-tenant buildings, tenant billing solutions ensure fair and transparent cost allocation based on actual energy usage. Automated metering and reporting streamline the billing process, eliminating disputes and enhancing tenant satisfaction. By integrating energy analytics, reporting, and tenant billing, businesses can optimize energy efficiency while maintaining financial transparency.

Emergent Energy Products and Services Brochures

Energy Monitoring Services

Overview of our Energy Monitoring and Analytics Services that supports our customers with their specific technology or consultative services.