How to Conduct an Energy Audit for Multisite Facilities

Energy costs are one of the largest controllable expenses for commercial and industrial facilities. As the US is faced with aging electrical infrastructure, large investments are needed to ensure grid reliability. Coupled with the electrification of our energy systems, the demand for electrical system capacity continues to grow. For this reason, multisite organizations that has inefficiencies within their energy system can multiply across locations—leading to significant energy waste and lost savings while being faced with increasing energy costs.

The solution? A well-executed energy audit that is paired with long-term (at least 3 months) energy monitoring. We highly suggest energy monitoring as a must have for successful energy audits because energy audits are typically performed over a series of a few days or weeks. The labor investment in the energy audit process can be significant as much time has to be spent on collecting equipment data and interviewing the facilities team. Due to the short duration of their audits, the audits are typically snapshots in time where the auditor might see a system and will end up carrying estimates on run hours, sequencing and energy loading.

Regardless of the site's sophistication, there is bound to be insufficient energy or operational data. As an example, if a building is old enough to need an energy audit, there is also a recognition of the possibility that the site is also old enough to lack the automation or centralized SCADA system that can collect the needed data that can maximize the value provided by a well informed energy audit. For this reason, each energy audit should be paired with an energy monitoring initiative that will collect critical energy metrics that can be trended over several weeks or months to provide the needed operational data to the auditor.

At Emergent Energy Solutions, we specialize in helping multisite companies identify, prioritize, and implement energy-saving opportunities. In this guide, we’ll walk you through how to conduct a successful energy audit—step-by-step.

What Is an Energy Audit?

An energy audit is a systematic review of energy usage within a facility to identify opportunities for improvement. It helps companies reduce utility costs, increase operational efficiency, and meet sustainability goals. There are many reasons our customers seek to have an audit performed. More recently, we have seen audit requests to meet benchmarking regulations throughout the major cities. Regulations have been set requiring carbon emission reductions that has proven challenging to large facilities and manufacturers that have high energy density from their operations.

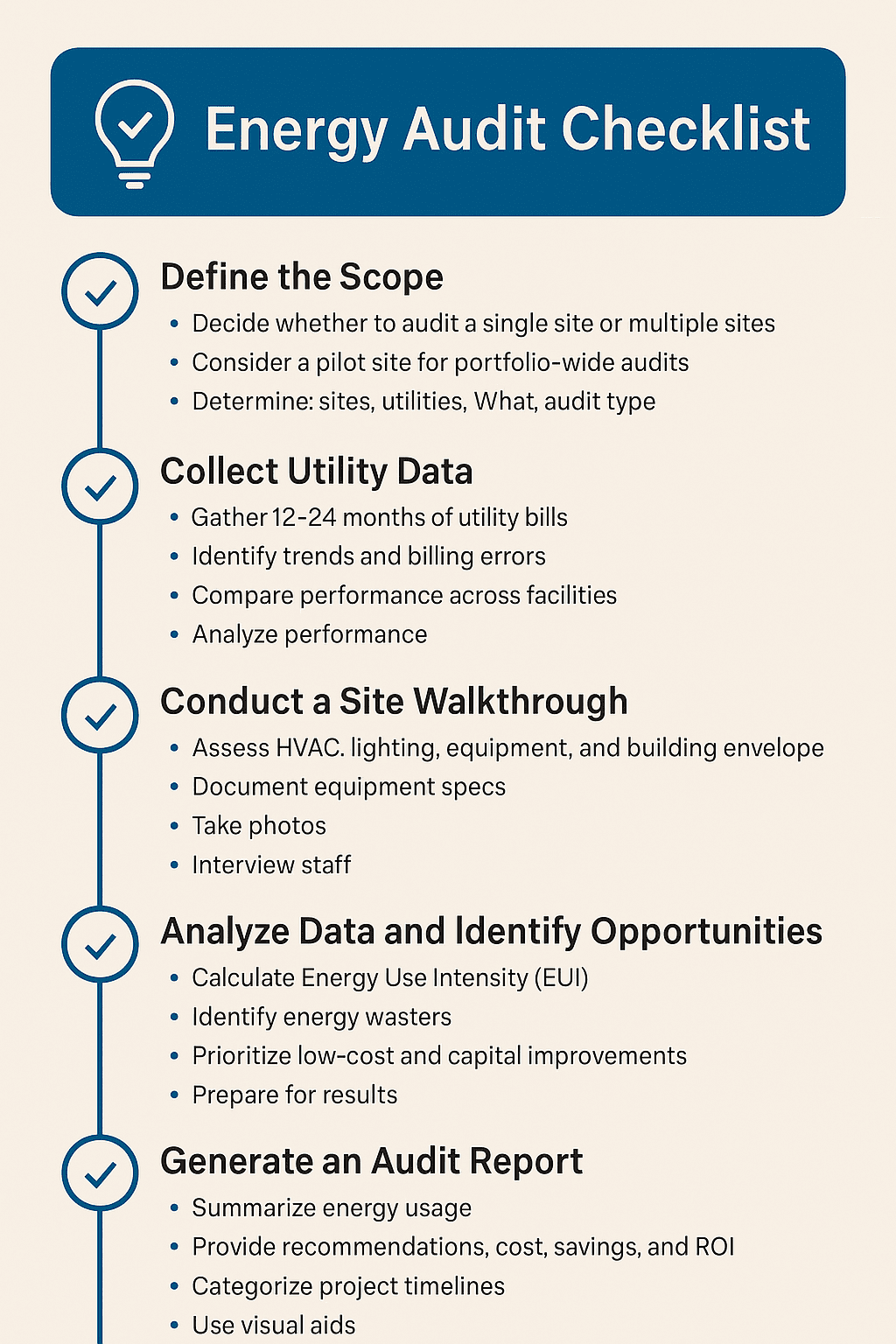

Step-by-Step Energy Audit Process

Step 1: Define the Scope

Decide whether you're auditing a single site or performing a portfolio-wide audit. For multisite companies, it’s often best to start with a pilot site and use the results to scale across other locations. With multi-site facilities, the best approach is to develop a template based on the initial pilot site. This will allow standardization of processes and efficiencies to be incorporated into the onsite auditing, documentation and survey process.

Key questions to consider:

Which sites use the most energy? The corporate energy engineer will likely have these details as they will be tasked with reduction goals they are trying to achieve.

Are you focusing on electricity, gas, water, or all utilities? It is also important to focus on secondary energy types such as compressed air, chilled water and and steam resources.

Do you want a basic walkthrough audit or a detailed investment-grade audit? What is the audit grade of interest. ASHRAE I or ASHRAE II audit?

Step 2: Collect Utility Data

Gather at least 12–24 months of utility bills for each site. Look for:

Energy usage trends (kWh, therms, gallons) - Are there any live metering data available through the site's automation system or process SCADA. This data is critical and will help drive focus for the audit.

Identify any metering needs to fill data gaps and to identify opportunities for the audit.

Peak demand charges

Seasonal variations

Billing errors or anomalies

Use benchmarking tools like ENERGY STAR Portfolio Manager or your own internal analytics platform to compare performance across facilities.

Step 3: Conduct a Site Walkthrough

Visit the facility (virtually or physically) to inspect:

HVAC systems, Building Automation Systems

Lighting (indoor/outdoor)

Motors, compressors, boilers, refrigeration equipment

Insulation and building envelope

Occupant behavior and schedules

Process loads

Take photos, interview staff, and document all relevant equipment specs and operational patterns.

Step 4: Analyze Data and Identify Opportunities

Use your collected data to:

Calculate Energy Use Intensity (EUI)

Determine where energy is being wasted

Identify quick wins (like lighting upgrades)

Highlight capital improvement opportunities (e.g., HVAC replacement, building automation)

Categorize recommendations by cost, ROI, and implementation timeline.

Step 5: Generate an Audit Report

Your audit report should include:

Energy usage summary

Identified issues and inefficiencies

Recommended improvements with savings estimates

ROI/payback periods

Photos, charts, and benchmarking comparisons

Make the report easy to share with stakeholders, especially if it’s part of a larger sustainability or capital planning effort.

Step 6: Create an Action Plan

Turn recommendations into an implementation roadmap:

Assign responsibilities (e.g., operations, facilities, finance)

Set timelines and milestones

Budget for low-cost and capital projects

Track progress using dashboards or monthly reports

Pro tip: Start with low-hanging fruit like scheduling changes or LED retrofits before tackling big-ticket upgrades.

What Happens After the Audit?

An energy audit is just the beginning. The key to long-term success is:

Ongoing monitoring of energy usage

Employee engagement and training

Periodic reassessments to track improvements and uncover new opportunities

Why Multisite Energy Audits Are Unique

Multisite organizations face added complexity:

Standardizing data across locations

Managing different equipment types or ages

Coordinating with multiple facility managers

That’s why we recommend using an experienced energy partner like Emergent Energy Solutions to streamline the process, centralize reporting, and prioritize projects with the biggest impact.

Ready to Get Started?

Whether you're managing 3 sites or 300, an energy audit is your first step toward reduced costs, improved sustainability, and smarter operations.

👉 Contact Emergent Energy Solutions today to schedule your facility assessment and start building your energy savings roadmap.